Polyethylene glycol melting point

Home » datasheet » Polyethylene glycol melting pointPolyethylene glycol melting point

Polyethylene Glycol Melting Point. Biomed Appl 6192251-257Kenyon AS Shi X Wang Y Ng WH Prestridge R Sharp K 1998. Mono ethylene glycol also known as MEG EG 12-ethanediol or 12-Dihydroxyethane is an organic compound with the formula C 2 H 6 O 2. ASTM Method D127-60 Standard Method of Test for. Vapor and saturation pressure for some common liquids.

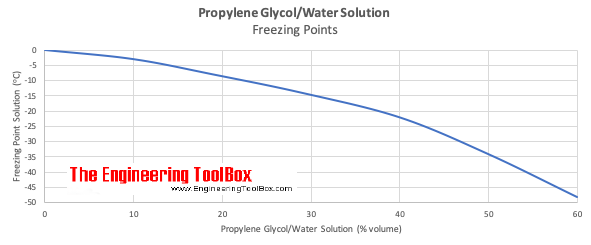

Propylene Glycol Based Heat Transfer Fluids From engineeringtoolbox.com

Propylene Glycol Based Heat Transfer Fluids From engineeringtoolbox.com

The commercial applicability of polyethylene is limited by its low melting point compared to other thermoplastics. ASTM Method D127-60 Standard Method of Test for. In contrast to the carbon-carbon links in the polymers discussed previously polyesters are based on carbonoxygencarbon links where one of the carbons is. Figure 2 Vanadiumv oxide catalyst used for the manufacture of sulfuric acid. Melting point is the temperature at which a given solid material changes from a solid state to a liquid or melts. Polyethylene Furanoate or PEF is a 100 recyclable bio-based polymer produced using renewable raw materials sugars derived from plants.

Ethylene glycol has been the most abundantly produced diol because it is one of the monomers of polyethylene terephthalate.

Liquid water properties at temperatures between melting point and boiling point and pressures of 147 psia 1000 psia and 10000 psia 1 atm 681atm and 681 atm Liquids - Freezing and Melting Points. Mono ethylene glycol also known as MEG EG 12-ethanediol or 12-Dihydroxyethane is an organic compound with the formula C 2 H 6 O 2. A small amount less than 1 is used to control insects in some stored agricultural products and a very small amount is used in hospitals to sterilize medical. This is expected to be a low hazard for usual industrial handling. Melting point - 16915 C - 27247 F 104 K. Figure 2 Vanadiumv oxide catalyst used for the manufacture of sulfuric acid.

Source: semanticscholar.org

Source: semanticscholar.org

Polyethylene terephthalate PET is a condensation polymer produced by the esterification of ethylene glycol EG with terephthalic acid TPA or dimethyl terephthalate DMT and has the general formula OOC C 6 H 5 COOCH 2 CH 2 n. PEF is referred as the next generation polyester which exhibits great potential to replace polyethylene terephthalate PET a durable polymer derived from conventional synthetic resources. Polyethylene glycol 2000 Revision Date 14-Feb-2020 US. Biomed Appl 6192251-257Kenyon AS Shi X Wang Y Ng WH Prestridge R Sharp K 1998. Common fluids and their freezing and melting points.

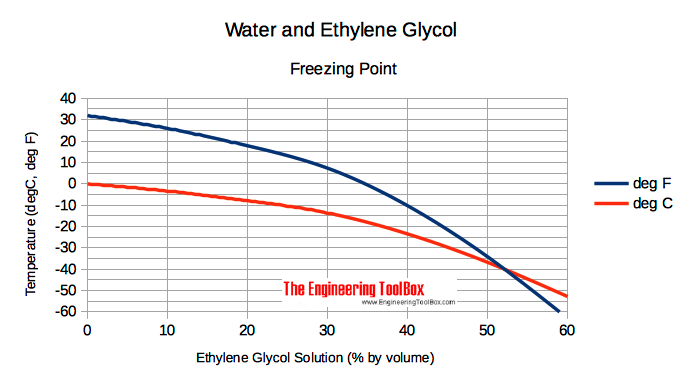

Source: engineeringtoolbox.com

Source: engineeringtoolbox.com

The function of the promoter is to lower the melting point of vanadiumV oxide so that it is molten at 700 K. Figure 2 Vanadiumv oxide catalyst used for the manufacture of sulfuric acid. The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F. Polyethylene glycol 3350 CAS NO. Common aliphatic diols are ethylene glycol 14-butanediol and 13-propanediol.

Source: dow.com

Source: dow.com

POLYETHYLENE GLYCOL 3350 1. Polyethylene Glycol Polymers have received much attention as suppository bases in recent years because they possess many desirable properties. Melting point - 16915 C - 27247 F 104 K. NN-Dioleoylethylenediamine NN-dilinoeoyl-ethylenediamine and N-oleoyl-N-linoleoyl-ethylenediamine mixture produced when tall oil fatty acids are made to react with ethylenediamine such that the finished mixture has a melting point of 212deg-228 degF as determined by ASTM method D127-60 and an acid value of 10 maximum. Weights of green kiln dried and.

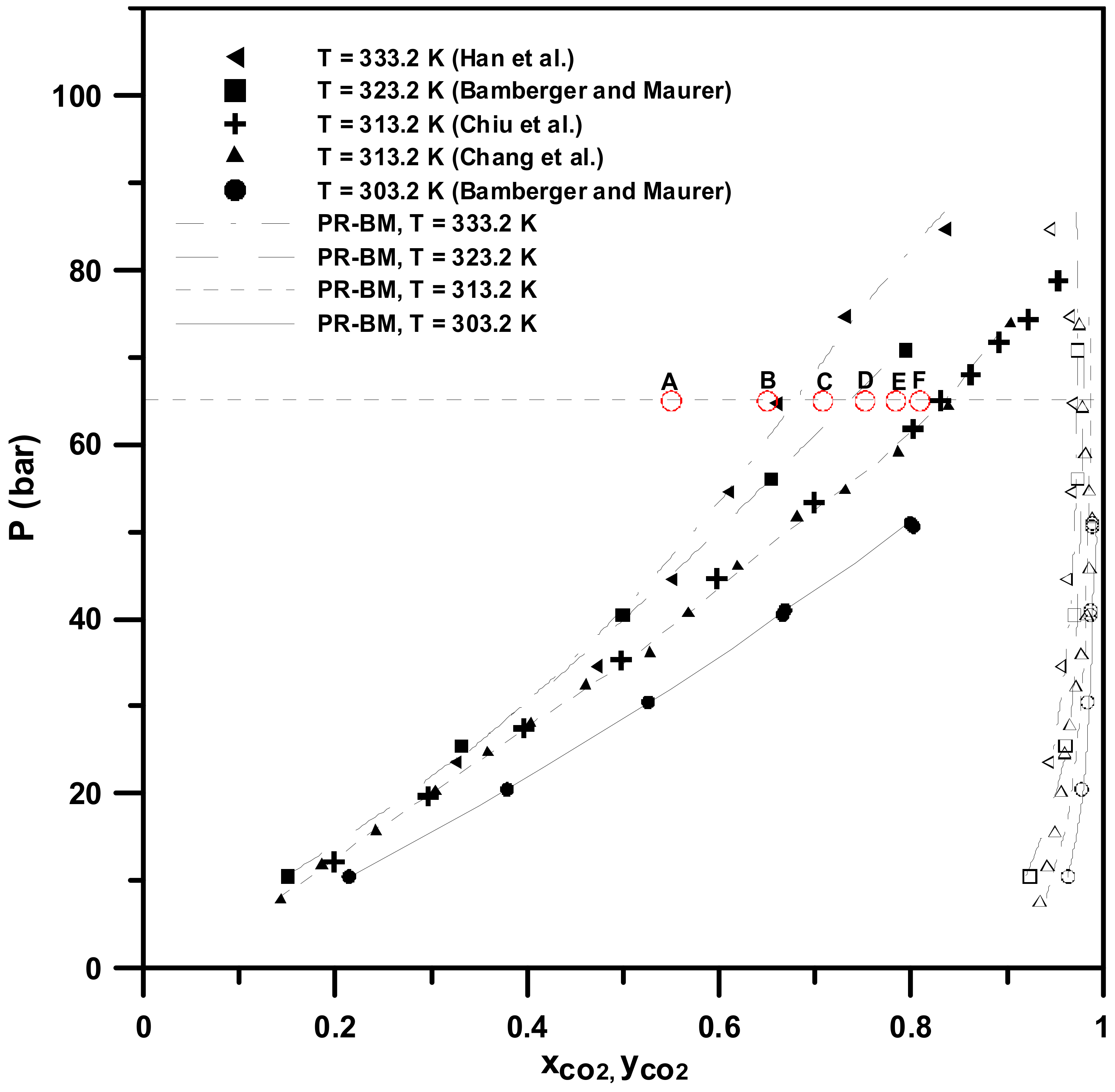

Source: researchgate.net

Source: researchgate.net

POLYETHYLENE GLYCOL 3350 1. Weights of green kiln dried and. Biomed Appl 6192251-257Kenyon AS Shi X Wang Y Ng WH Prestridge R Sharp K 1998. The commercial applicability of polyethylene is limited by its low melting point compared to other thermoplastics. Fusca cutinase in common with other cutinases has a number of small patches of both acidic and basic residues distributed over the surface conferring a more neutral pI of 63 Fig.

Source: americanpharmaceuticalreview.com

Source: americanpharmaceuticalreview.com

For common commercial grades of medium- and high-density polyethylene the melting point is typically in the range 120 to 130 C 248 to 266 F. Simple at-site detection of diethylene glycolethylene glycol contamination of glycerin and glycerin- based raw. 23 PEGs are water-soluble polymers that can form hydrogen bonds in a ratio of 100 water molecules per one PEG molecule. Polyethylene Glycol 3350 Synonymn. 2075382 Btulb 1152988 kcalkg.

Source: researchgate.net

Source: researchgate.net

Its miscible with water alcohols and many other organic compounds and is primarily used in the industry for manufacturing polyester. A new class of greener rocket propellants comprising polyurethanes based on recycled PET as the binder phase stabilized ammonium nitrate PSAN as. When prolonged or frequently repeated contact could occur use protective clothing chemically resistant to this material. 13 35 Jm. ASTM Method D127-60 Standard Method of Test for.

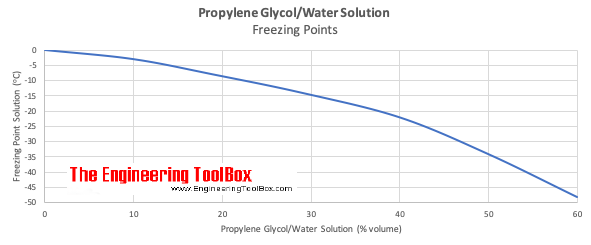

Source: engineeringtoolbox.com

Source: engineeringtoolbox.com

Vapor and saturation pressure for some common liquids. Polyethylene Glycol 400 WEEL TWA Particulate 10 mgm3 Personal Protection EyeFace Protection. 513887 Btulb 285492 kcalkg. Aromatic reactants improve the hardness rigidity and heat resistance whereas aliphatic acids and diols increase the flexibility lower the melting or softening point and improve the processability. Good laboratory procedures are.

Source:

Fusca cutinase in common with other cutinases has a number of small patches of both acidic and basic residues distributed over the surface conferring a more neutral pI of 63 Fig. Usually ethylene is supplied from the thermal cracking of naptha from petroleum refining. Novel polyurethane-based binders specifically designed for environmentally responsible rocket propellant composites were obtained by employing the polyester-polyols that resulted from the degradation of polyethylene terephthalate waste. For common commercial grades of medium- and high-density polyethylene the melting point is typically in the range 120 to 130 C 248 to 266 F. PETase has a highly polarized surface charge Fig.

Source:

A small amount less than 1 is used to control insects in some stored agricultural products and a very small amount is used in hospitals to sterilize medical. Like glycerinated gelatin they do not melt at body temperature. A colourless viscous hygroscopic low-melting -59 and high-boiling 188 liquid with low toxicity it is used as a solvent emulsifying agent and antifreeze. Mono ethylene glycol also known as MEG EG 12-ethanediol or 12-Dihydroxyethane is an organic compound with the formula C 2 H 6 O 2. 23 PEGs are water-soluble polymers that can form hydrogen bonds in a ratio of 100 water molecules per one PEG molecule.

Source: mdpi.com

Source: mdpi.com

PEF is referred as the next generation polyester which exhibits great potential to replace polyethylene terephthalate PET a durable polymer derived from conventional synthetic resources. ASTM Method D127-60 Standard Method of Test for. Simultaneous determination of ethylene glycol propylene glycol 13-butylene glycol and 23-butylene glycol in human serum and urine by wide-bore column gas chromatography. The commercial applicability of polyethylene is limited by its low melting point compared to other thermoplastics. Polyethylene glycol PEG is a synthetic polymer produced via polymerization of ethylene oxide molecules to make joining units of ethylene glycol by an ether linkage.

If you find this site good, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title polyethylene glycol melting point by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.