Polyethylene density at vapor point

Home » datasheet » Polyethylene density at vapor pointPolyethylene density at vapor point

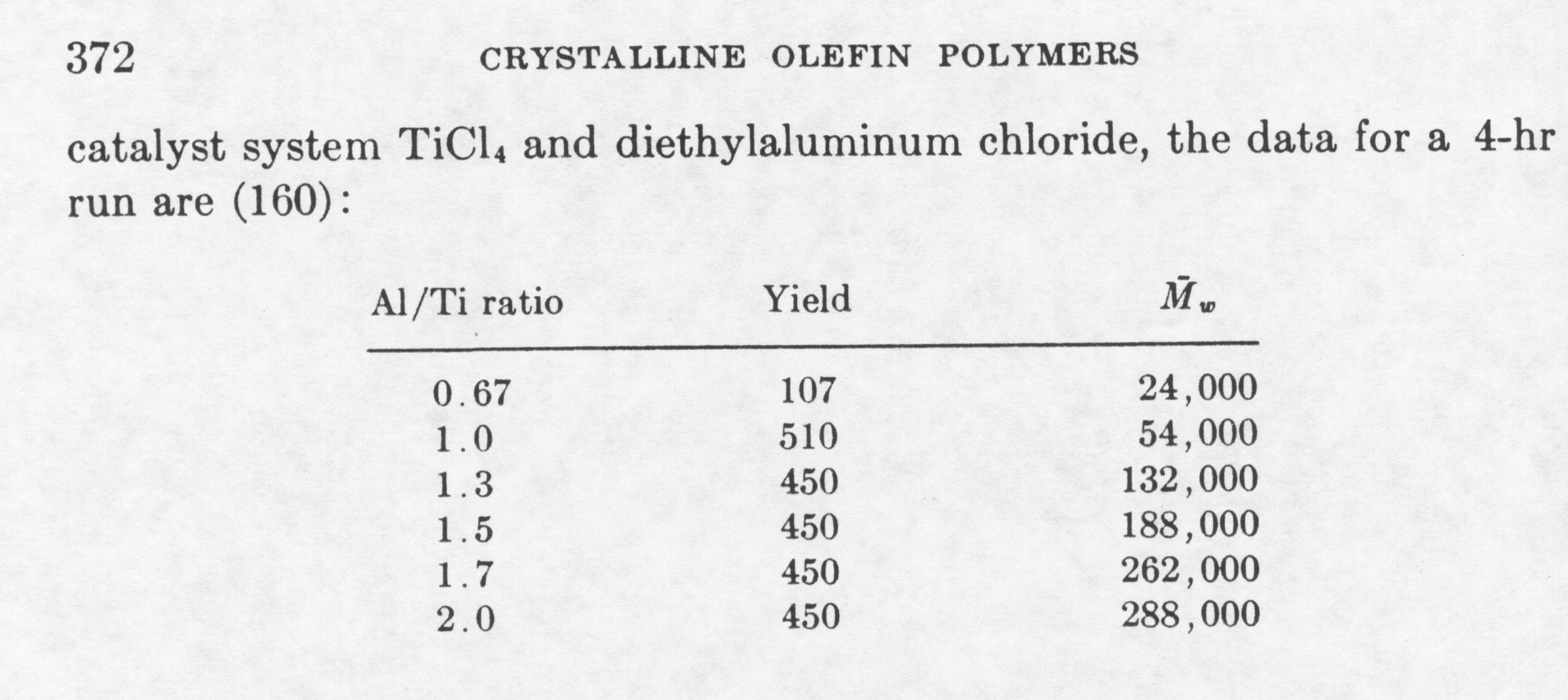

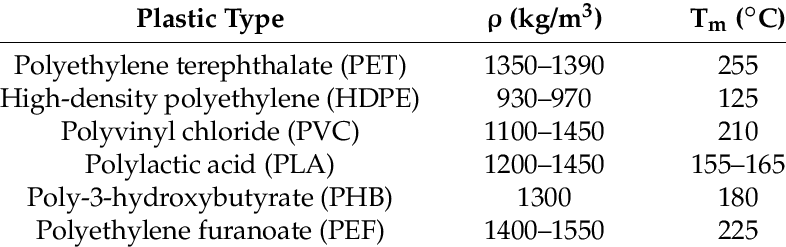

Polyethylene Density At Vapor Point. The symbol most often used for density is ρ the lower case Greek letter rho although the Latin letter D can also be used. It also has a high melting point which differentiates it from polyethylene. They offer smart options for improved service life safety and sustainability by producing extremely durable leak- and corrosion-resistant flexible pipe. Instead of burning thermoplastics like polyethylene liquefy which.

Everything You Need To Know About Polyethylene Pe From creativemechanisms.com

Everything You Need To Know About Polyethylene Pe From creativemechanisms.com

View chapter Purchase book. The term LLDPE is an acronym for linear low-density polyethylene. Puncture resistance and elongation than LDPE. Polyethylene terephthalate PET Most common thermoplastic. Properties of Low-Density Polyethylene. DMT and TPA are solids.

Heat capacity at constant pressure Cp.

Thermoplastic materials become liquid at their melting point 110-130 degrees Celsius in the case of LDPE and HDPE respectively. It also has a high melting point which differentiates it from polyethylene. Heat capacity at constant pressure Cp. Its high toughness ductility excellent chemical resistance low water vapor permeability and very low water absorption combined the ease with which it can be processed make PE of all different density grades an attractive choice for a. The term LLDPE is an acronym for linear low-density polyethylene. Where ρ is the density m is the mass and V is the volume.

Source: researchgate.net

Source: researchgate.net

Good laboratory procedures are. In some cases. Both processes first produce the intermediate bis-2-hydroxyethyl-terephthalate BHET monomer and either methanol DMT process or water TPA process. Where ρ is the density m is the mass and V is the volume. ABS PolyAcrylonitrile Butadiene Styrene ACM PolyAcrylic Acid Ester Rubber ACS Acrylonitrile-Chlorinated Polyethylene-Styrene Terpolymer ACS American Chemical Society AES PolyAcrylonitrile Ethylene Styrene or PolyAcrylonitrile Ethylene Propylene Styrene AMMA PolyAcrylonitrile Methyl Methacrylate AN Acrylonitrile AO Antioxidant APET Amorphous Polyethylene Terephthlate API.

Source: wwwcourses.sens.buffalo.edu

Source: wwwcourses.sens.buffalo.edu

HDPE high-density polyethylene J diffusion flux LDPE low-density polyethylene MVTR moisture vapor transmission rate PNNL Pacific Northwest National Laboratory P permeability PS polystyrene PVT polyvinyl toluene S solubility STP standard temperature and pressure exactly 27315 K and 100 kPa VTR vapor transmission rate. Where ρ is the density m is the mass and V is the volume. Mathematically density is defined as mass divided by volume. Polyethylene glycol diglycidyl bisphenol A polymer. The typical density of this resin is 0950 gcc and higher.

Source: researchgate.net

Source: researchgate.net

We know it doesnt work because of field experience. Thermoplastic materials become liquid at their melting point 110-130 degrees Celsius in the case of LDPE and HDPE respectively. DMT and TPA are solids. A hinge made out of polypropylene can be opened and closed many many times and hold up just fine. The density more precisely the volumetric mass density.

Source: sciencedirect.com

Source: sciencedirect.com

The BHET monomer is then polymerized under reduced pressure with heat and catalyst to. For common commercial grades of medium- and high-density polyethylene the melting point is typically in the range 120 to 130 C 248 to 266 F. Like LDPE LLDPE has good water vapor barrier properties but is a poor barrier to oxygen carbon dioxide and many odor and flavor compounds Abdel-Bary 2003. The term HDPE is an acronym for high-density polyethylene. Its high toughness ductility excellent chemical resistance low water vapor permeability and very low water absorption combined the ease with which it can be processed make PE of all different density grades an attractive choice for a.

Source: researchgate.net

Source: researchgate.net

Both processes first produce the intermediate bis-2-hydroxyethyl-terephthalate BHET monomer and either methanol DMT process or water TPA process. DMT and TPA are solids. Instead of burning thermoplastics like polyethylene liquefy which. Natural gas water distribution and oil and gas are among the applications that benefit from the remarkable. Puncture resistance and elongation than LDPE.

Source: sciencedirect.com

Source: sciencedirect.com

The glib way to answer your question about using a polyethylene vapor barrier to keep concrete walls dry would be The reason we know that it doesnt work is because thousands of builders have tried it and thousands of remodelers and home performance contractors have had to clean up the moldy mess caused by these failures. Since LLDPE often permits considerable downgaging it can be the lowest cost alternative on a per-use basis. The density more precisely the volumetric mass density. Temperature resistance up to 80C continuously and 95C for shorter times. For common commercial grades of medium- and high-density polyethylene the melting point is typically in the range 120 to 130 C 248 to 266 F.

Source: researchgate.net

Chemical resistance of LDPE. Its high toughness ductility excellent chemical resistance low water vapor permeability and very low water absorption combined the ease with which it can be processed make PE of all different density grades an attractive choice for a. PEG 3350 Chemical formula. High-density spray foam due to its vapor semi impermeable characteristics should be used in place of low-density foam in very cold and subarcticarctic regions. One area where polyethylene has over polypropylene is that polyethylene is more stable.

Source: quora.com

Polypropylene has the advantage that it can take repeated motions such as being a hinge. We know it doesnt work because of field experience. Also known as specific mass of a substance is its mass per unit volume. One area where polyethylene has over polypropylene is that polyethylene is more stable. Mild Hazards of product.

Source: polymerdatabase.com

Source: polymerdatabase.com

This is expected to be a low hazard for usual industrial handling. Polypropylene has the advantage that it can take repeated motions such as being a hinge. We know it doesnt work because of field experience. The selection of a vapor retarderbarrier material and its level of permeance should be made on the basis of the protective requirements of the material being applied to the floor surface or the environment being protected. Underneath the basement or on-grade slab floor install a capillary break and vapor diffusion retarder consisting of a layer of 6- to 10-mil polyethylene over at least 4 inches of gravel.

Source: creativemechanisms.com

Source: creativemechanisms.com

This is expected to be a low hazard for usual industrial handling. Also known as specific mass of a substance is its mass per unit volume. WVTR water vapor transmission rate is the steady state rate at which water vapor permeates through a film at specified conditions of temperature and relative humidity. A useful attribute of thermoplastics is that they can be heated to their melting point cooled and reheated again without significant degradation. The term HDPE is an acronym for high-density polyethylene.

If you find this site convienient, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title polyethylene density at vapor point by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.