Pe ld melting point

Home » datasheet » Pe ld melting pointPe ld melting point

Pe Ld Melting Point. Class 40 HS 232 mmm2 40 IACS 82 gcm3 770 MPa 5 Tin Silver Designation Density Melting point Symbol Tin 9990 729 gcm3 232 C Sn. To DIN EN 13602 Cu-ETP1 5858 mmm2 Copper clad steel wire Staku 40. This type of plastic material does not have a sharp melting point but softens to a melt over a broad range of temperature. Over 12000 phrases and expressions.

Polyethylene Wikipedia From en.wikipedia.org

Polyethylene Wikipedia From en.wikipedia.org

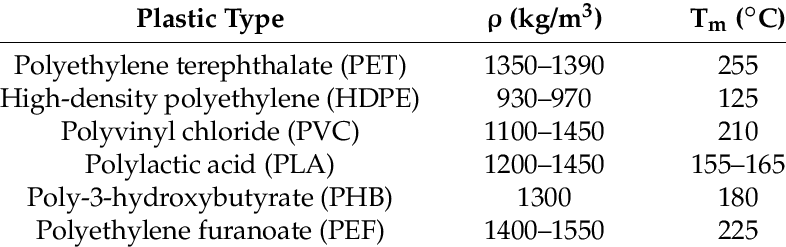

The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F. When the process is not controlled properly the outer layer of the tube may become brittle. These temperatures vary strongly with the type of polyethylene but the theoretical upper limit of melting of polyethylene is reported to be 144 to 146 C 291 to 295 F. Polyethylene consists of nonpolar saturated. Melting point Copper acc. It provides less uniform lower-degree cross-linking than the Engel method especially at tube diameters over one inch 25 cm.

To DIN 40500 Part 4 E-Cu 58 F 21 20065 580 mmm2 89 gcm3 210 MPa 21 1083 C Copper acc.

Over 12000 phrases and expressions. Polyethylene consists of nonpolar saturated. To DIN 40500 Part 4 E-Cu 58 F 21 20065 580 mmm2 89 gcm3 210 MPa 21 1083 C Copper acc. It therefore can be molded or processed over a comparatively wide temperature range. A major advantage of amorphous polymers is their low and consistent shrinkage relative to that of semi-crystalline materials. Combustion typically occurs above 349 C 660 F.

Source: en.wikipedia.org

Source: en.wikipedia.org

It provides less uniform lower-degree cross-linking than the Engel method especially at tube diameters over one inch 25 cm. These plastics tend to be flexible and difficult to break at room temperature. It provides less uniform lower-degree cross-linking than the Engel method especially at tube diameters over one inch 25 cm. To DIN 40500 Part 4 E-Cu 58 F 21 20065 580 mmm2 89 gcm3 210 MPa 21 1083 C Copper acc. Polyethylene consists of nonpolar saturated.

Source: en.wikipedia.org

Source: en.wikipedia.org

PELD -120 to -100 Note. The largest dictionary of idioms and phrases currently in use in British American and Australian English. All Indian Sex Videos can be downloaded 100 free at Hindipornvideosinfo. To DIN 40500 Part 4 E-Cu 58 F 21 20065 580 mmm2 89 gcm3 210 MPa 21 1083 C Copper acc. It therefore can be molded or processed over a comparatively wide temperature range.

Source: en.wikipedia.org

Source: en.wikipedia.org

However it is the cleanest most environmentally. Over 12000 phrases and expressions. However it is the cleanest most environmentally. It therefore can be molded or processed over a comparatively wide temperature range. The latest local weather crime politics events and more.

When the process is not controlled properly the outer layer of the tube may become brittle. As the natural color of an amorphous material is generally. It therefore can be molded or processed over a comparatively wide temperature range. Watch for FREE over 100000 Indian xxx videos. Over 12000 phrases and expressions.

Source: rowak.ch

Source: rowak.ch

However it is the cleanest most environmentally. Polyethylene consists of nonpolar saturated. A major advantage of amorphous polymers is their low and consistent shrinkage relative to that of semi-crystalline materials. Read the latest breaking Omaha News and headlines for the Midlands Region of Nebraska from the Omaha World-Herald. A domesticated carnivorous mammal Canis familiaris syn.

Source: researchgate.net

Source: researchgate.net

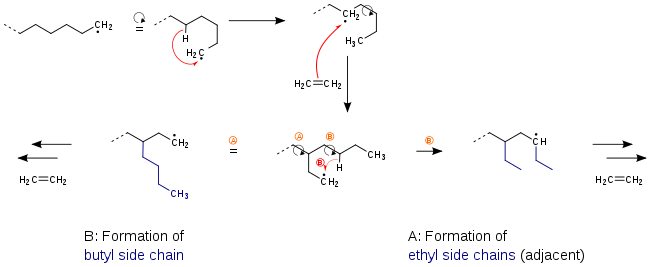

PELD -120 to -100 Note. One of the most significant special cases is. These temperatures vary strongly with the type of polyethylene but the theoretical upper limit of melting of polyethylene is reported to be 144 to 146 C 291 to 295 F. PEX-C is produced through electron beam processing in a cold cross-linking process below the crystal melting point. Polyethylene consists of nonpolar saturated.

Source: en.wikipedia.org

Source: en.wikipedia.org

All Indian Sex Videos can be downloaded 100 free at Hindipornvideosinfo. One of the most significant special cases is. A domesticated carnivorous mammal Canis familiaris syn. The latest local weather crime politics events and more. When the process is not controlled properly the outer layer of the tube may become brittle.

Source: en.wikipedia.org

Source: en.wikipedia.org

The largest dictionary of idioms and phrases currently in use in British American and Australian English. A major advantage of amorphous polymers is their low and consistent shrinkage relative to that of semi-crystalline materials. PEX-C is produced through electron beam processing in a cold cross-linking process below the crystal melting point. Polyethylene consists of nonpolar saturated. The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F.

Source: researchgate.net

Source: researchgate.net

This type of plastic material does not have a sharp melting point but softens to a melt over a broad range of temperature. To DIN EN 13602 Cu-ETP1 5858 mmm2 Copper clad steel wire Staku 40. Familiaris occurring as a wide variety of breeds many of which are traditionally used for hunting herding drawing sleds and other tasks and are kept as pets. These plastics tend to be flexible and difficult to break at room temperature. However it is the cleanest most environmentally.

Source: researchgate.net

Source: researchgate.net

The largest dictionary of idioms and phrases currently in use in British American and Australian English. Polyethylene consists of nonpolar saturated. PEX-C is produced through electron beam processing in a cold cross-linking process below the crystal melting point. Melting point Copper acc. These temperatures vary strongly with the type of polyethylene but the theoretical upper limit of melting of polyethylene is reported to be 144 to 146 C 291 to 295 F.

If you find this site beneficial, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title pe ld melting point by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.