Pdms melting point

Home » datasheet » Pdms melting pointPdms melting point

Pdms Melting Point. The range of controllable stiffness realized through these materials however is very narrow so the maximum demonstrated payload-to-weight ratio has been 17 with a lowmelting point alloy 15 16. These properties can be easily and quicky determined by DSC. On the other hand Cast steel contains less than 2 carbon. Boiling Point C Feature.

Polydimethylsiloxane Wikipedia From en.wikipedia.org

Polydimethylsiloxane Wikipedia From en.wikipedia.org

00051 mgl at 25C. Melting point C. 645 -38 -30 -68. Nucleic acid extraction NAE is one of the most pivotal steps in molecular biology being routinely used in many areas of the biological and medical sciences as this procedure marks a starting point in any molecular diagnostic kit This crucial procedure has been known for over a century and has developed substantially over the last decades. Melting point temperature range 0 C Glass transition temperature range 0 C Polyethylene High Density ABS Tg. Press New York 1999 Youngs modulus.

The transparent PDMS acts as optical element of varying focal point distance depending on its curvature.

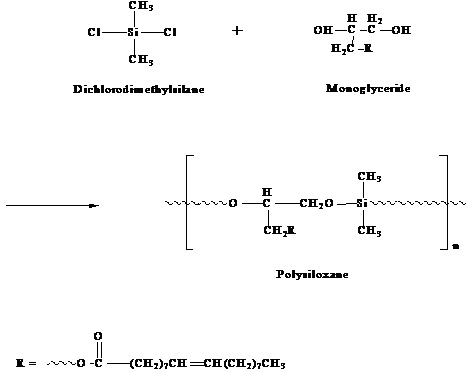

PDMS is the most widely used silicon-based organic polymer as its versatility and properties lead to many applications. Melting Point C Physical Form. Melting point C. 1570 mgl at 25C. On the other hand Cast steel contains less than 2 carbon. Polymer Data Handbook Mark J Oxford Univ.

Source: researchgate.net

Source: researchgate.net

More recently work shows that graphene on PDMS exhibits reversible responses to large applied strain. 09 at 25 C. 645 -38 -30 -68. PDMS presents however several drawbacks. It is then pulled up quickly at first and then slowly to solidify silicon on the seed crystal by rotating both.

Source: en.wikipedia.org

Source: en.wikipedia.org

These properties can be easily and quicky determined by DSC. Analytical 63 ACS reagent 44 Puriss 35 Cell Culture 21 Reagent 18 Purum 17 Anhydrous 13 BioXtra 13 ReagentPlus 11 Plant 7 Show More. P03AX05 Hazards NFPA 704 fire diamond 1. NA vitrifies Pharmacology ATC code. PDMS presents however several drawbacks.

Source: researchgate.net

Source: researchgate.net

15 Most Common Welding Defects Causes and Remedies With PDF Written by Anup Kumar Dey. The magnetotransport measurements were conducted in a four-point geometry with gold contacts under. A PDMS stamp is first put into contact on a substrate the relief pattern facing towards the substrate. Boiling point C. Boiling Point C Feature.

Source: sciencedirect.com

Source: sciencedirect.com

P03AX05 Hazards NFPA 704 fire diamond 1. DSC measurements before and after the topology transformation revealed that the melting enthalpy a measure of crystallinity of both crystalline blocks ie PDMS and PVL blocks increased after. Infobox references 3-Aminopropyltriethoxysilane APTES is an aminosilane frequently used in the process of silanization the functionalization of surfaces with alkoxysilane molecules. Cast iron is a ferrous material containing more than 2 carbon. The novelty of the work was to determine the influence of the percentage of MP content and physiological conditioning on the properties of the PDMS-MP composites after in vitro incubation.

Source:

This is facilitated by the formation of an electrostatically stabilized enzymepolymer surfactant nanoconstruct which after lyophilization and melting affords stable macromolecular dispersions in a wide range of organic solvents. More recently work shows that graphene on PDMS exhibits reversible responses to large applied strain. These properties can be easily and quicky determined by DSC. Then the melted paraffin was scraped from one end to the other using a blade so that the paintPA photothermal surface was evenly coated with the melted paraffin wax. 09 at 25 C.

Source:

Then the melted paraffin was scraped from one end to the other using a blade so that the paintPA photothermal surface was evenly coated with the melted paraffin wax. Physicochemical properties- It is generally accepted that the best drug candidates for passive adhesive Transdermal patches must be Non-ionic. To 1250C CHCH2 CH CHCH2 CH Polyacrylamide. In 1979 at Three Mile Island in USA a cooling malfunction caused part of the TMI 2 core to melt. Welding defects can be defined as unacceptable imperfection during the welding process.

Source:

P03AX05 Hazards NFPA 704 fire diamond 1. Infobox references 3-Aminopropyltriethoxysilane APTES is an aminosilane frequently used in the process of silanization the functionalization of surfaces with alkoxysilane molecules. Analytical 63 ACS reagent 44 Puriss 35 Cell Culture 21 Reagent 18 Purum 17 Anhydrous 13 BioXtra 13 ReagentPlus 11 Plant 7 Show More. Welding defects can be defined as unacceptable imperfection during the welding process. It is then pulled up quickly at first and then slowly to solidify silicon on the seed crystal by rotating both.

Source: researchgate.net

Source: researchgate.net

PDMS presents however several drawbacks. Here we describe a facile route to the synthesis of enzymatically active highly fabricable plastics where the enzyme is an intrinsic component of the material. Cast iron is a ferrous material containing more than 2 carbon. Press New York 1999 Youngs modulus. The magnetotransport measurements were conducted in a four-point geometry with gold contacts under.

Source: polydimethylsiloxane.blogspot.com

Source: polydimethylsiloxane.blogspot.com

Infobox references 3-Aminopropyltriethoxysilane APTES is an aminosilane frequently used in the process of silanization the functionalization of surfaces with alkoxysilane molecules. The freestanding membranes were transferred onto thin PDMS sheets for magnetization measurements. In the CZ method which is the most commonly used growth method in the industry polysilicon granules are put into a quartz crucible and heated in vacuum up to about 1420 C just above the melting point of silicon. Then a seed crystal of silicon is dipped into the molten silicon. Melting Point C Physical Form.

Source:

The freestanding membranes were transferred onto thin PDMS sheets for magnetization measurements. 1570 mgl at 25C. Infobox references 3-Aminopropyltriethoxysilane APTES is an aminosilane frequently used in the process of silanization the functionalization of surfaces with alkoxysilane molecules. The novelty of the work was to determine the influence of the percentage of MP content and physiological conditioning on the properties of the PDMS-MP composites after in vitro incubation. Reports on interdisciplinary polymer science and on.

If you find this site good, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title pdms melting point by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.