Melting point of ldpe

Home » datasheet » Melting point of ldpeMelting point of ldpe

Melting Point Of Ldpe. The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F. Rockwell Hardness R-Scale ASTM D 785. The plastic recycling code of LDPE is 4. Tensile Strength at Yield kgcm 2 ASTM D 638 Crosshead speed 50 mmmin.

Melting Points Of The Rpws Download Table From researchgate.net

Melting Points Of The Rpws Download Table From researchgate.net

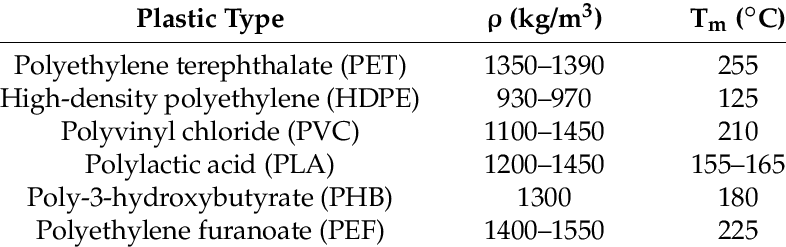

Thermoplastic materials become liquid at their melting point 110-130 degrees Celsius in the case of LDPE and HDPE respectively. It includes recyclable non-recyclable mixed plastics and biodegradable plastics. Tensile strength at Break kgcm 2 ASTM D 882. Syrup ketchup and medicine. ICORENE 1505 BLACK 9001 is a crosslinkable natural high density polyethylene specifically developed for rotational moulding. However once its reached its melting point the plastic material can be quickly and efficiently molded for use across a variety of unique applications including cutting boards detergent bottles milk jugs food storage containers corrosion-resistant piping geomembranes plastic lumber and so much more.

HDPE is also.

Plastic number 7 has a wide range of plastics with many different characteristics. It is made by copolymerizing. LDPE and HDPE are thermoplastic materials under the family of polyolefins which are petrochemical-based plastics that include polypropylene PP and polyethylene PEPolyethylene is the most common plastic material in the world and is known for its simple structure the simplest of all polymers commercially available. Long chains linked together by crosslinking arms to form a network of chains eg cured thermosets such as vinyl ester. The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F. Rockwell Hardness R-Scale ASTM D 785.

Source: researchgate.net

Source: researchgate.net

And it is uneconomical to. Long chains linked together by crosslinking arms to form a network of chains eg cured thermosets such as vinyl ester. Limited resistance to aliphatic and aromatic hydrocarbons mineral oils oxidizing agents and halogenated hydrocarbons. LDPE can be found in squeezable condiment bottles and toys but its mostly used in plastic films. And it is uneconomical to.

Source: wiki.zero-emissions.at

Source: wiki.zero-emissions.at

HDPE has a higher density than LDPE which means that the former has more mass than its volume. Low cost polymer with good processability. Rockwell Hardness R-Scale ASTM D 785. LDPE and HDPE are thermoplastic materials under the family of polyolefins which are petrochemical-based plastics that include polypropylene PP and polyethylene PEPolyethylene is the most common plastic material in the world and is known for its simple structure the simplest of all polymers commercially available. Long chains with arms coming from branch points eg LDPE Network.

Source: researchgate.net

Source: researchgate.net

It includes recyclable non-recyclable mixed plastics and biodegradable plastics. Polypropylene or PP has a high melting point that makes it great for containing hot liquids. Collectively under the polyethylene class of materials LDPE low-density. Long chains linked together by crosslinking arms to form a network of chains eg cured thermosets such as vinyl ester. Plastic Number 7 is a complex group.

Source: researchgate.net

Source: researchgate.net

Long chains linked together by crosslinking arms to form a network of chains eg cured thermosets such as vinyl ester. Tensile strength at Break kgcm 2 ASTM D 882. A useful attribute of thermoplastics is that they can be heated to their melting point cooled and reheated again without significant degradation. However once its reached its melting point the plastic material can be quickly and efficiently molded for use across a variety of unique applications including cutting boards detergent bottles milk jugs food storage containers corrosion-resistant piping geomembranes plastic lumber and so much more. Polypropylenes high melting point makes it suitable for microwaveable food containers.

Source: researchgate.net

Source: researchgate.net

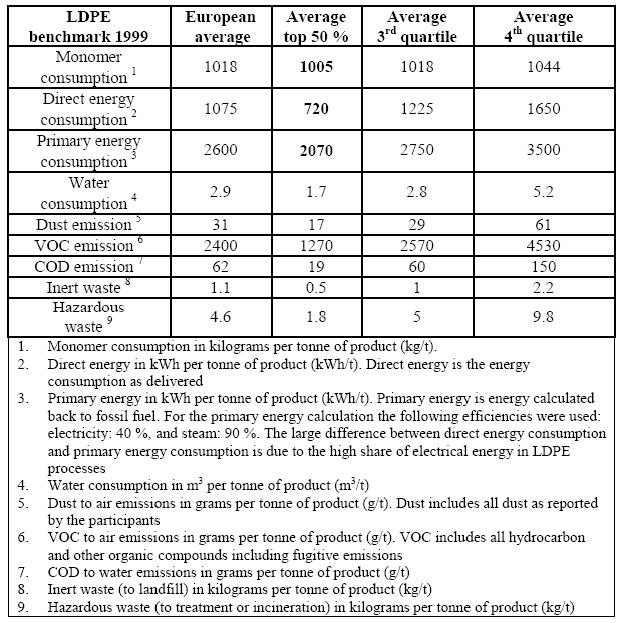

Lets discuss the melting point of all the mainstream plastic materials with a defined table. It has less mass than HDPE which is why its considered a separate material for recycling. Some people may term HDPE as crystalline but it is more appropriate to restrict it in the category of semi. That means shrink wrap as well as bags dry cleaning grocery bread frozen food and produce bags all qualify. HDPE is also.

This specification is to be implemented by Germany and the other EU countries as early as 2020. These temperatures vary strongly with the type of polyethylene but the theoretical upper limit of melting of polyethylene is reported to be 144 to 146 C 291 to 295 F. Polyethylene consists of nonpolar saturated. Sharp melting point Poor formability Opaque Good chemical resistance Difficult to bond using adhesives or solvents Resistant to stress cracking Good fatigue resistance Good for bearing and wear as well as structural applications IMIDIZED MATERIALS Best physical properties above 400ºF Best temperature resistance Best bearing and wear capabilities Good chemica. The melting point for average commercial low-density polyethylene is typically 105 to 115 C 221 to 239 F.

These temperatures vary strongly with the type of polyethylene but the theoretical upper limit of melting of polyethylene is reported to be 144 to 146 C 291 to 295 F. Polypropylenes high melting point makes it suitable for microwaveable food containers. SCG PP P722JO is an impact copolymer polypropylene resin which contains UV stabilizer this resin is recommened for. Syrup ketchup and medicine. However once its reached its melting point the plastic material can be quickly and efficiently molded for use across a variety of unique applications including cutting boards detergent bottles milk jugs food storage containers corrosion-resistant piping geomembranes plastic lumber and so much more.

Source: researchgate.net

Source: researchgate.net

Limited resistance to aliphatic and aromatic hydrocarbons mineral oils oxidizing agents and halogenated hydrocarbons. Low cost polymer with good processability. HDPE is also. LLDPE is structurally similar to LDPE. Its melting point is approximately 110 C 230 F.

Source: slideplayer.com

Source: slideplayer.com

HDPE is also. Tensile strength at Break kgcm 2 ASTM D 882. Packaging and containers made from LDPE make up about 56 of allplastic waste 75 of which comes from residential households. Melting point and glass transition temperature of polymer. LDPE was the first polyethylene to be produced making it the grandfather of the material.

Source: researchgate.net

Source: researchgate.net

Instead of burning thermoplastics like polyethylene liquefy which allows them to be easily. Low cost polymer with good processability. However they must be recycled separately. Principal uses are in packaging film trash and grocery bags agricultural mulch wire and cable insulation squeeze bottles toys and housewares. Chemical resistance of LDPE.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title melting point of ldpe by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.