Melting point of acrylic

Home » datasheet » Melting point of acrylicMelting point of acrylic

Melting Point Of Acrylic. 105 C 221 F Injection Mold Temperature. It also will not darken or deteriorate from exposure to fluorescent light. The idea is to get good clean chips from your cut without any melting of the plastic as its being cut. It is also a reagent in the.

Poly Methyl Methacrylate Wikipedia From en.wikipedia.org

Poly Methyl Methacrylate Wikipedia From en.wikipedia.org

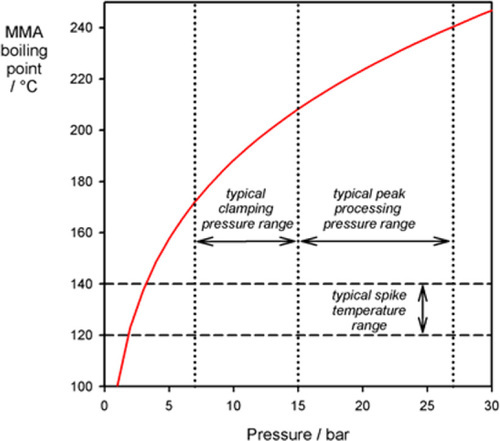

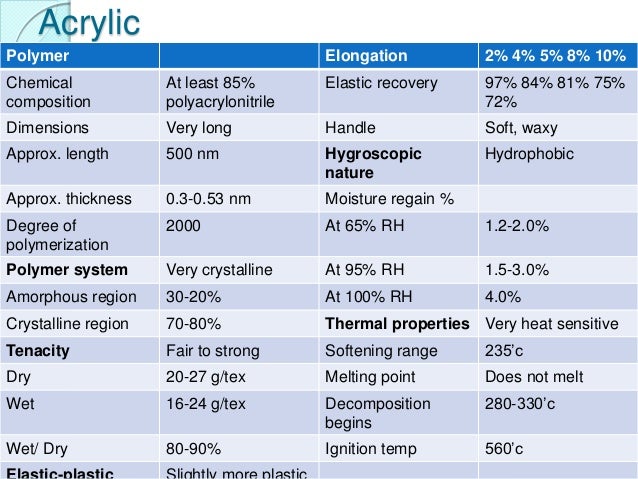

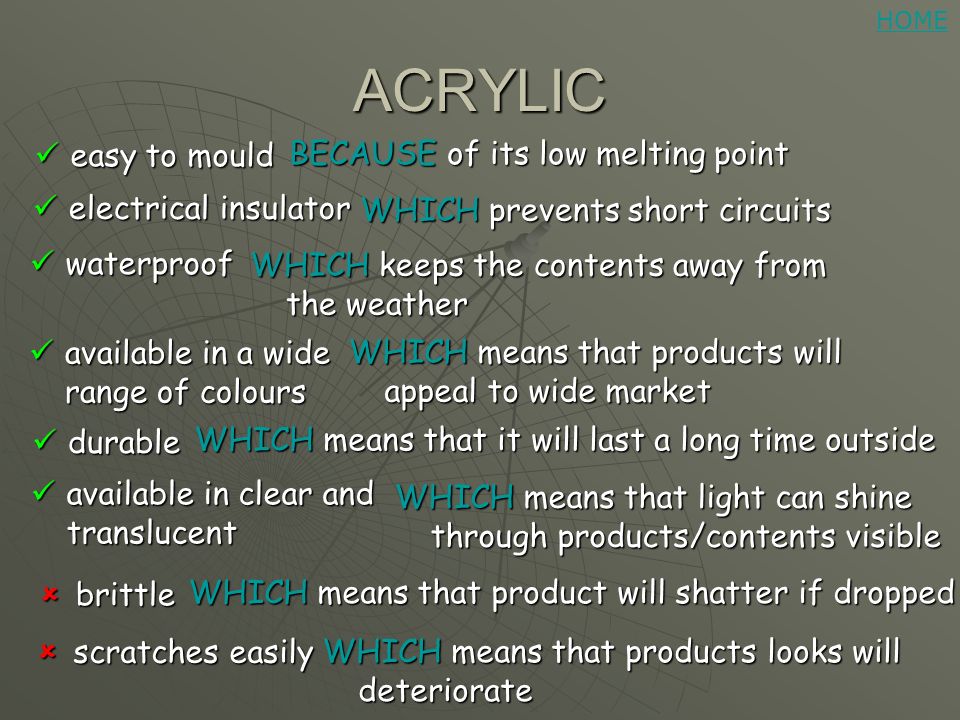

It happens that the material is first heated to the level of melting point. The thermoplastic part refers to the nature of polycarbonate and other similar plastics to become liquid at their melting point which allows among other things for easy injection molding and recycling. A major useful attribute about thermoplastics is that they can be heated to their melting point cooled and reheated again without significant. Our tests have shown the above to. Due to its malleability and low melting point this acrylic is better suited to laser cutting routing and polishing as well as cementing and thermoforming. Amorphous no true melting point.

The melting point of acrylic is 160C and it should be noted that the material begins to deform at temperatures below this.

Melting Point Definition A specific temperature range in which a polymer reveals a transition from ordered to disordered resulting from heating is called the Melting point. EPDM CLEANERACTIVATOR is. While you can use a faster RPM you might have to increase your feed rate to prevent melting of the plastic. It happens that the material is first heated to the level of melting point. 1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 2 4p 6 4d 10 4f 14 5s 2 5p 6 5d 10 6s 2 6p 3. During the process of cross-linking the molecular weight of the polymer increases.

Source: pocketdentistry.com

Source: pocketdentistry.com

Due to its malleability and low melting point this acrylic is better suited to laser cutting routing and polishing as well as cementing and thermoforming. A major useful attribute about thermoplastics is that they can be heated to their melting point cooled and reheated again without significant. Extruded acrylic is more affordable and dimensionally stable than cast acrylic making it a cost-effective solution in general fabrication and a wide range of applications. Esters ketones ethylene dichloride and acetone not water soluable. Dont worry too much as the melting point of acrylic is 160C.

Source: en.wikipedia.org

Source: en.wikipedia.org

The melting point for acrylic plastic is 160 degrees Celcius so they cannot withstand extreme temperatures. Dont worry too much as the melting point of acrylic is 160C. EPDM CLEANERACTIVATOR is. After all whether or not you know your Braque from your Baroque those strangely melting. This colorless liquid has a characteristic acrid or tart smell.

Source: creativemechanisms.com

Source: creativemechanisms.com

One inch 25cm thick acrylic prism featuring amazing designs on a back-mounted print. Salvador Dalis iconic painting The Persistence of Memory is quite probably one of the most famous works of art in the entire world along with Da Vincis Mona Lisa Picassos Guernica and a few othersand certainly it is the most-recognizable surrealist painting ever created. 9747 gramcm 3 at 20 C 68 F oxidation states 3 5. It is a colourless liquid with a characteristic acrid odor. Propenoic acid is an organic compound with the formula CH 2 CHCOOH.

Source: pt.slideshare.net

Source: pt.slideshare.net

Hence the melting point increases. Plexiglas is an intelligent material. Due to its malleability and low melting point this acrylic is better suited to laser cutting routing and polishing as well as cementing and thermoforming. We started our journey in the. Extruded acrylic is more affordable and dimensionally stable than cast acrylic making it a cost-effective solution in general fabrication and a wide range of applications.

Source: creativemechanisms.com

Source: creativemechanisms.com

Acrylic withstands years of exposure to the elements and even corrosive atmospheres without losing its transparency gloss or dimensional shape. We started our journey in the. Dont worry too much as the melting point of acrylic is 160C. One inch 25cm thick acrylic prism featuring amazing designs on a back-mounted print. Thermoplastic materials become liquid at their melting point 160 degrees Celsius in the case of Acrylic.

Source: goodfellow.com

Source: goodfellow.com

Bismuth evidently was known in very early times since it occurs in the native state as well as in compounds. Is acrylic suitable for secondary glazing. Some acrylic has been known to last up to 30 years when left in the outdoors. Deflection temperatures of glass fiber or carbon fiber reinforced engineering polymers can approach the melting point of the base resin. It can withstand high stresses for short periods and is one of the most scratch-resistant thermoplastics.

Source: brightbeecraft.com

Source: brightbeecraft.com

It is miscible with water alcohols ethers and chloroformMore than a million tons are produced annually. Hence the melting point increases. The result is an eye catching touch that enlightens. Explore the site today. However the deflection temperature test is a short-term test and should not be used alone for product design.

Source: creativemechanisms.com

Source: creativemechanisms.com

The result is an eye catching touch that enlightens. The thermoplastic part refers to the nature of polycarbonate and other similar plastics to become liquid at their melting point which allows among other things for easy injection molding and recycling. 1s 2 2s 2 2p 6 3s 2 3p 6 3d 10 4s 2 4p 6 4d 10 4f 14 5s 2 5p 6 5d 10 6s 2 6p 3. High quality Acrylic Blocks by independent artists and designers from around the world. It also will not darken or deteriorate from exposure to fluorescent light.

Source: en.wikipedia.org

Source: en.wikipedia.org

Extruded acrylic is also less susceptible to dirt lint or. Is acrylic suitable for secondary glazing. It is miscible with water alcohols ethers and chloroformMore than a million tons are produced annually. While you can use a faster RPM you might have to increase your feed rate to prevent melting of the plastic. The deflection temperature test results are a useful measure of relative service temperature for a polymer when used in load-bearing parts.

Source: slideplayer.com

Source: slideplayer.com

The melting point for acrylic plastic is 160 degrees C so they cannot withstand extreme temperatures. Bismuth evidently was known in very early times since it occurs in the native state as well as in compounds. Salvador Dalis iconic painting The Persistence of Memory is quite probably one of the most famous works of art in the entire world along with Da Vincis Mona Lisa Picassos Guernica and a few othersand certainly it is the most-recognizable surrealist painting ever created. The melting point for acrylic plastic is 160 degrees Celcius so they cannot withstand extreme temperatures. Windows larger than 800mm will benefit from being glazed with a thicker sheet to provide rigidity.

If you find this site adventageous, please support us by sharing this posts to your own social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title melting point of acrylic by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.