Electrostatic spray melting point

Home » datasheet » Electrostatic spray melting pointElectrostatic spray melting point

Electrostatic Spray Melting Point. The replacement air during the heating seasons shall be maintained at not less than 65 deg. Flammability solid gas Extremely flammable gas. As a result of our experience with this product and our knowledge of its composition we do. Not flammable Lower explosion limit.

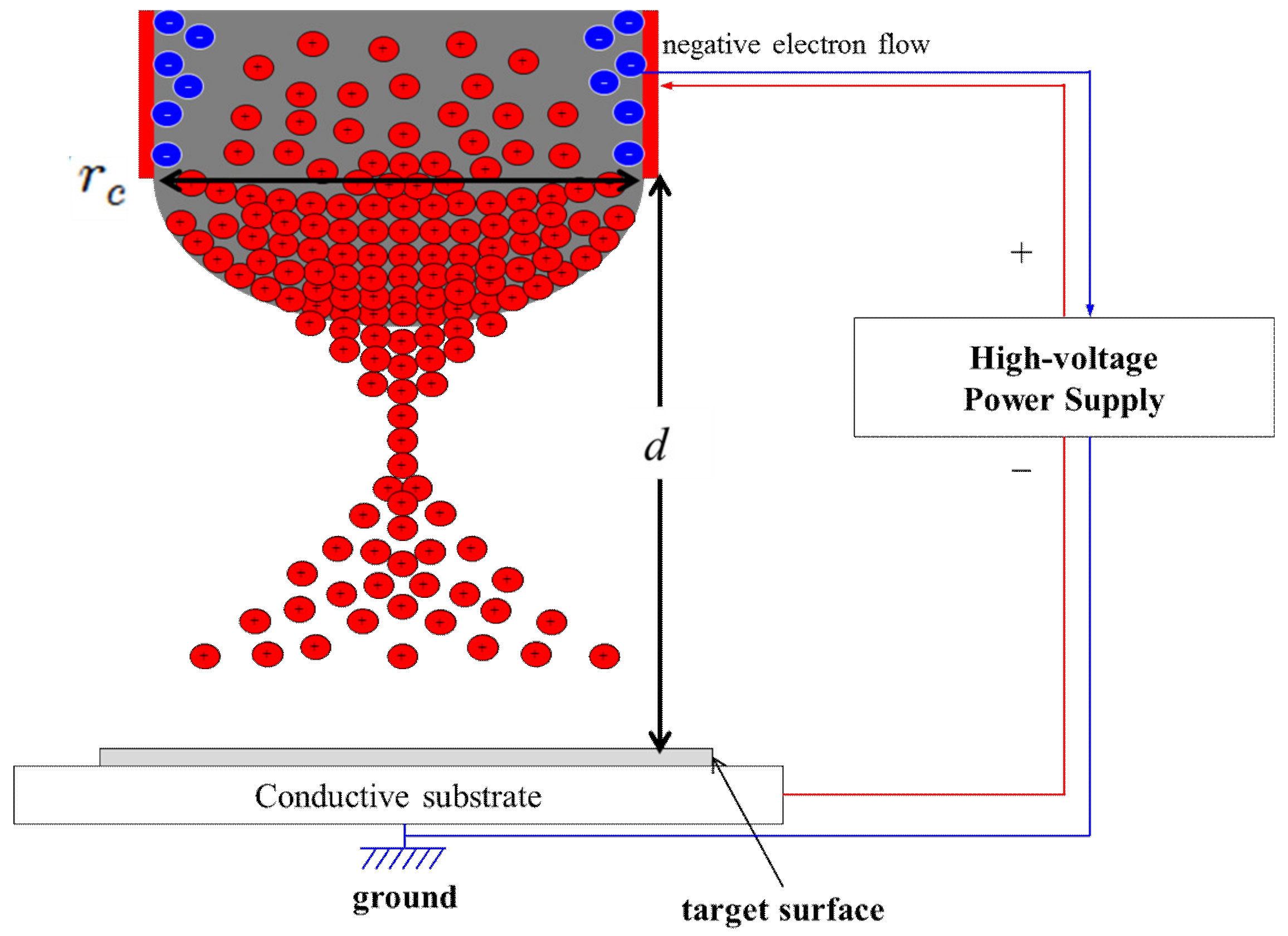

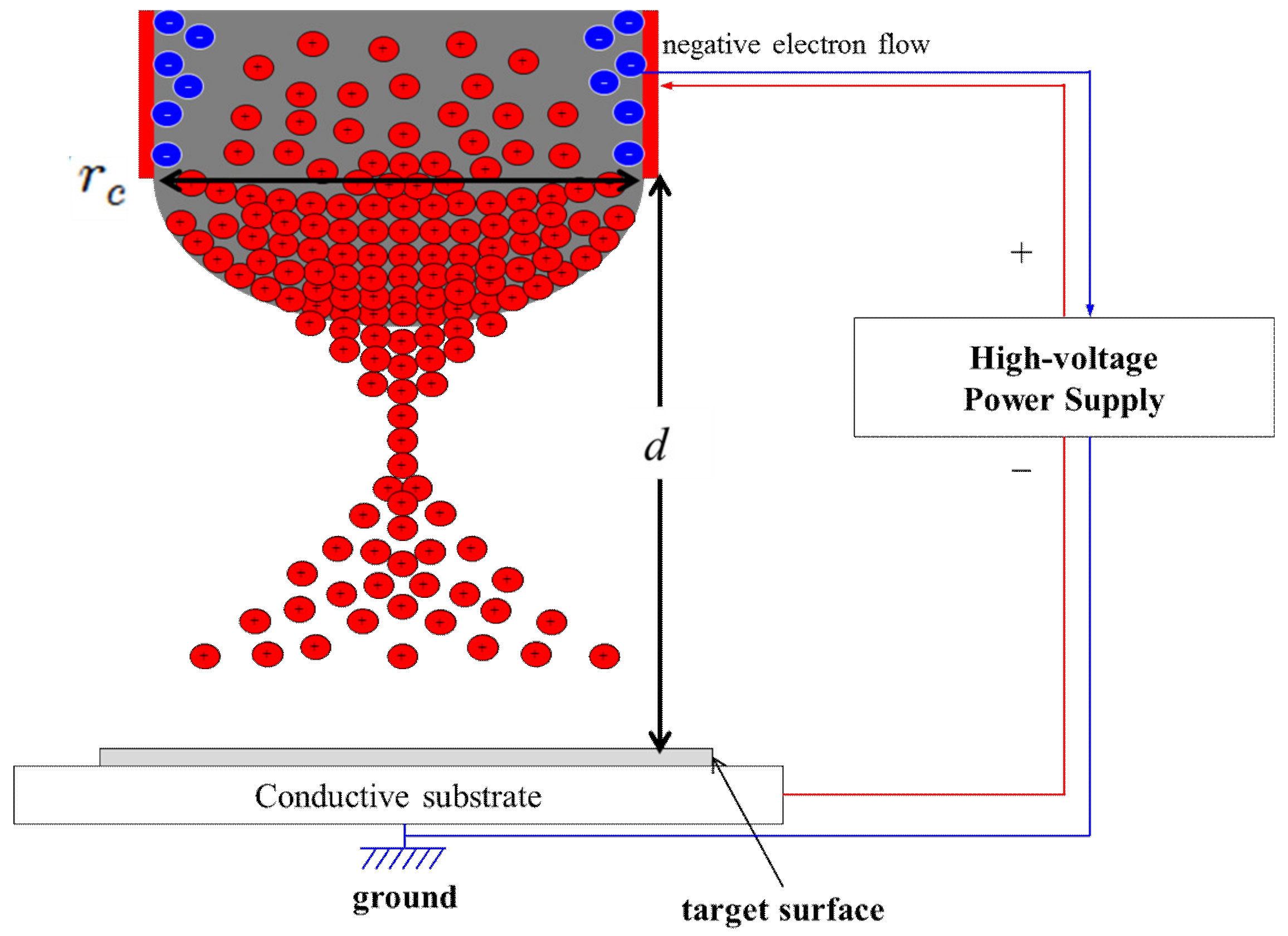

Coatings Free Full Text Experimental Qualification Of The Process Of Electrostatic Spray Deposition Html From mdpi.com

Coatings Free Full Text Experimental Qualification Of The Process Of Electrostatic Spray Deposition Html From mdpi.com

Thermal spraying techniques are coating processes in which melted or heated materials are sprayed onto a surface. NTP 1992 NTP 1992 53 Special protective actions for fire-fighters. The sharp melting endotherm of curcumin was absent in the temperature range of the endotherm of microcapsules. Melting pointfreezing point Melting pointrange. Below room temperature its temperature shall be regulated as provided in section 363 of ANSI Z92-1960. Avoid breathing vapors or spray mists of the product.

2500 C Evaporation rate.

Not applicable Flammability liquids. Thermal spraying techniques are coating processes in which melted or heated materials are sprayed onto a surface. SAFETY DATA SHEET PURELL Advanced Hand Sanitizer Sanitizing Gel Version 10 SDS Number. C at the point of entry into the spray booth or spray room. Research Triangle Park North Carolina. However the melting enthalpy of microcapsules was just 676 Jg possibly due to partial denaturation and melting of maltodextrin and HI-CAP during spray drying.

Source: researchgate.net

Source: researchgate.net

113 156C 60F Typical Density. Not flammable Lower explosion limit. When a sufficiently high voltage is applied to a liquid droplet the body of the liquid becomes charged and electrostatic repulsion counteracts the surface tension and the droplet is stretched. Melting pointfreezing point. Also it could be concluded.

Source: researchgate.net

Source: researchgate.net

However the amide units also form strong interactions with water causing the polyamides to absorb water. 7000 C Flash point. Not flammable Lower explosion limit. -10850 C Boiling point. Upperlower flammability or explosive limits Explosive limit - lower 215.

Source: researchgate.net

Source: researchgate.net

NTP 1992 NTP 1992 53 Special protective actions for fire-fighters. The powder is then cured heated to its melting point so that it flows to form a smooth film. Flash point data for this chemical are not available. -10850 C Boiling point. This can holds 12 ounces of foam that expands after spraying.

Source: chinapowdercoating.com

Source: chinapowdercoating.com

Page 111 Safety Data Sheet acc. When otherwise unheated make-up air would be at a temperature of more than 10 deg. As a result of our experience with this product and our knowledge of its composition we do. 113 156C 60F Typical Density. Below room temperature its temperature shall be regulated as provided in section 363 of ANSI Z92-1960.

Source: aip.scitation.org

Source: aip.scitation.org

140F 40C MELTING POINT. Melting pointfreezing point Melting pointrange. 350 mm Hg at 68F 20C VAPOUR DENSITY air 10. 270 Electrostatic interactions in particular between basic residues or bound Ca 2 ions and anionic phospholipid headgroups contribute to the subcellular targeting of many other peripheral. -98 C -144 F Boiling point 647 C 1485 F Flash point 97 C 495 F - closed cup Ignition temperature 455 C 851 F Auto-ignition temperature 4550 C 8510 F at 1013 hPa 760 mmHg Lower explosion limit 6 V Upper explosion limit 36 V.

Source: researchgate.net

Source: researchgate.net

This is ideal for. Melting pointfreezing point. 180C 356F Estimated Solubility. 230 CDIN 51794 Self ignition. Below room temperature its temperature shall be regulated as provided in section 363 of ANSI Z92-1960.

Source: researchgate.net

Source: researchgate.net

Mild Steel Shot Blasting Again using our Hodge Clemco. No data available Evaporation Rate. 230 CDIN 51794 Self ignition. Upper explosion limit. Use water spray to cool unopened containers.

Source: sciencedirect.com

Source: sciencedirect.com

When a sufficiently high voltage is applied to a liquid droplet the body of the liquid becomes charged and electrostatic repulsion counteracts the surface tension and the droplet is stretched. The powder is then cured heated to its melting point so that it flows to form a smooth film. NTP 1992 NTP 1992 53 Special protective actions for fire-fighters. Once your order has been blasted we can either powder coat or wet spray to your desired RAL colour in our 5000Sq Ft Paint Shop. Techspray is a leading manufacturer of chemical products and soldering tools for the electronic plant and equipment maintenance industry.

Source: mdpi.com

Source: mdpi.com

04212020 3 10 Suitable extinguishing media. Find answers safety data sheets and product specs here. Also it could be concluded. National Toxicology Program Chemical Repository Database. Not applicable Flammability liquids.

Source: bunzlcanada.ca

Source: bunzlcanada.ca

Use an appropriate respirator when adequate ventilation is not available. No data available Initial boiling point and boiling range. Research Triangle Park North Carolina. Section 5 - Fire Fighting Measures Section 6 - Accidental Release Measures Section 7 - Handling and Storage. Not applicable Flammability liquids.

If you find this site serviceableness, please support us by sharing this posts to your preference social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title electrostatic spray melting point by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.